- Technologies

- Laser Technologies

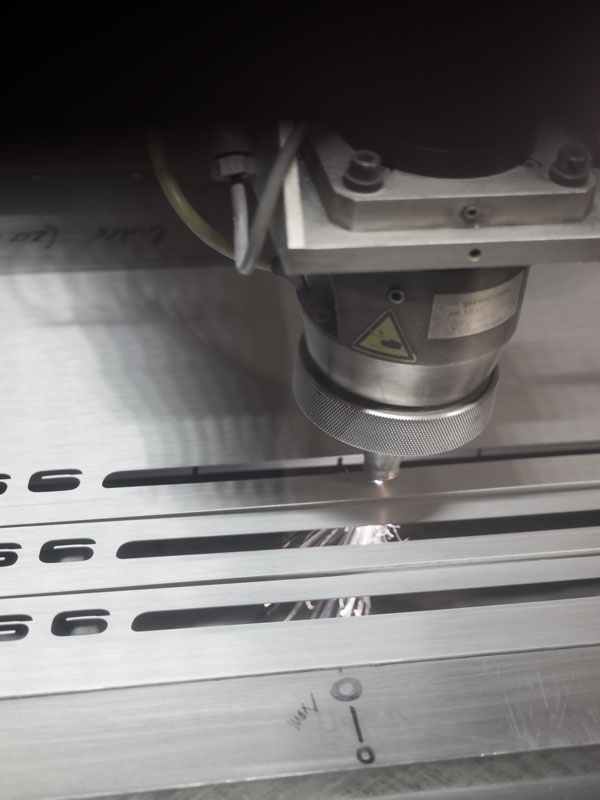

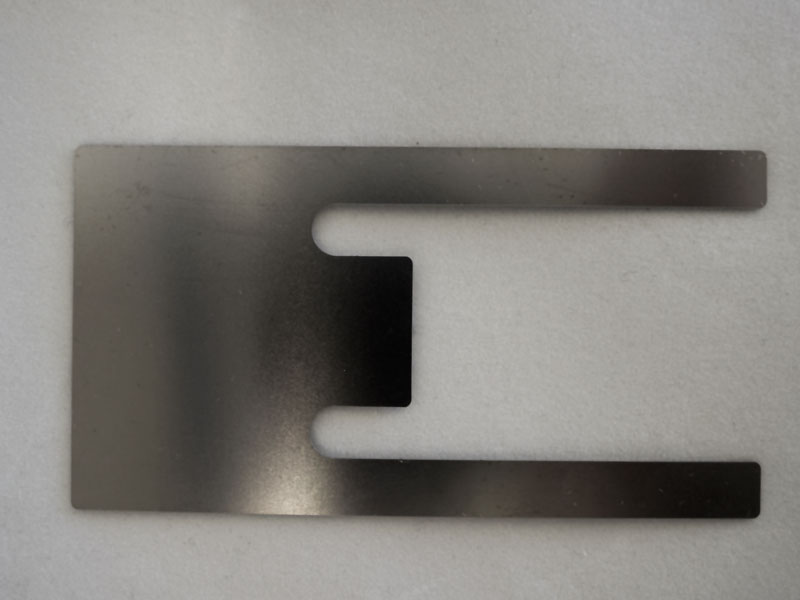

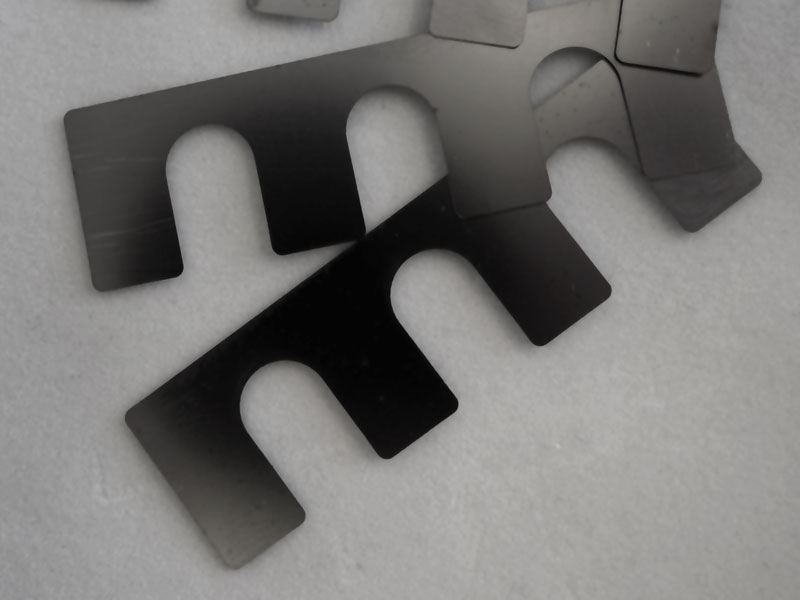

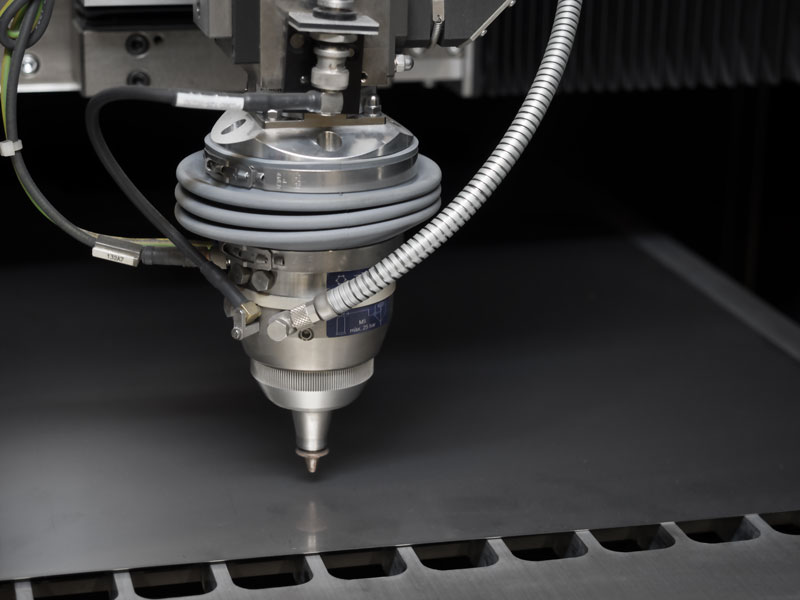

Laser cutting and laser welding

We unite the newest laser technologies and machines for the farther processing. For example: bending of small metal parts with our precision bending machine.

|

The laser cutting and fine laser cutting is used where complicated outlines an exact and quick processing and a force-free processing are requested. With the laser we reach narrow cuts, the results are precision cut components. The procedure has low torsion and often makes reworks superfluous, because the thermal load on the component is very low and most materials can be cut nearly freely of burr. Our production range reaches from thin foils of 0.01 mm up to thin sheets with maximum 4.0 mm of strength. Drillings and cutting gap from 20 µm can be realized. Modern CAD/CAM technology realize nearly any contour wish. Complicated geometry of the Semiconductor Research as well as electronics components or design wishes and letterings. In our laser machining we use molybdenum, tantalum, niobium, nickel, wolfram, Invar, Inconel, titan as well as many other metals. |

|

Different components of an assembly are connected with each other by laser welding in the sub-millimeter range. This technology is used in areas in which other welding procedures are not practicable because of the thermal load or the small component size. The technology of the fine laser welding has also proved itself with the component fixing with welding spots. With the help of micro laser welding under microscope almost all metals can be connected reliably and with high precision with each other. |

Laser Cutting

Laser Cutting